45 Auto RIM

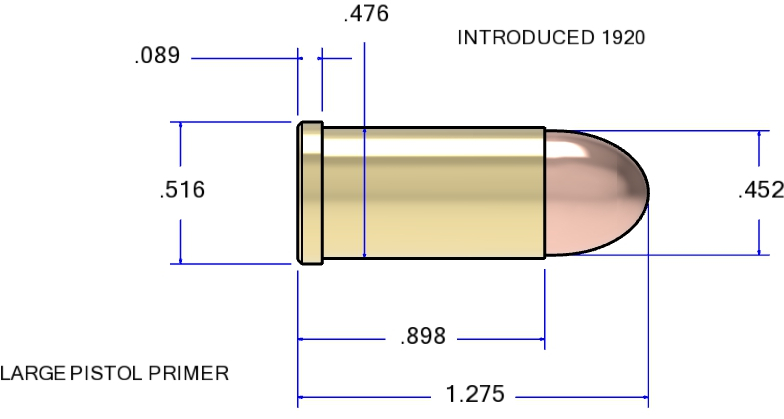

The .45 Auto Rim (AR) cartridge was introduced in 1920 by Peters Cartridge Company for use in .45 ACP revolvers, such as the M1917 revolvers made by Smith & Wesson and Colt. These revolvers were initially designed to use .45 ACP cartridges with half-moon or full-moon clips. The .45 Auto Rim, however, features a rimmed case that eliminates the need for these clips, simplifying the loading and extraction process in revolvers.

The cartridge typically fires a .45 caliber (0.452") bullet, similar to the .45 ACP, and delivers comparable ballistic performance, with velocities and energy suited for both self-defense and target shooting. The .45 Auto Rim is less common today but still produced by several manufacturers for enthusiasts and owners of vintage revolvers.

The design facilitates an easier and more convenient use in specific revolvers, making it popular for shooters interested in historical firearms or those preferring revolvers over semi-automatic pistols for the .45 caliber round.

question_answer Join Discussion (1 comment) add remove

Welcome to our cartridge knowledge base, featuring expert insights from M. L. (Mic) McPherson on a wide range of cartridges. Whether you're new or experienced, discover practical tips and share your field experiences to enrich our community. Please no disparaging remarks on other writers and no powder load data. Help shape a valuable resource for all enthusiasts. If you find anything factually incorrect, we want to hear about it! If you have any interesting comments or reloading tricks that you would like to share on this cartridge, share them here!

Please Log in to post a comment.- format_quoteformat_quote

| Die Sets |

|---|

| Lee Full-Length Sizing Die Set |

| 90808 (Carbide 3-Die set) |

| Lee Breech Lock Die Set |

| Lee Loader |

| Single Dies |

|---|

| Full-Length Sizing Die |

| Sizing Die |

| Powder through Expanding Die |

| 90585 |

| Charging Die |

| Factory Crimp Die |

| 90864 (Carbide) 92162 (Micrometer Adapter) 92250 (Carbide) |

| Taper Crimp Die |

| 90785 |

| Die Accessories |

|---|

| Micrometer Adjuster |

| 92162 92150 |

| Guided Decapper |

| 91584 |

| Case Conditioning Tools |

|---|

| Case Length Gauge and Shell Holder |

| 90162 |

| Quick Trim Die |

| 90073 |

| Presses |

|---|

| Reloader Press (50 RPH) |

| 90045 (Lee Reloader Press) |

| Hand Press (50 RPH) |

| Breech Lock Hand Presses |

| Challenger Press (50 RPH) |

| 90588 (Challenger III) 90050 (50th Anniversary Challenger Kit) 90030 (Challenger Kit) |

| Classic Cast Press (50 RPH) |

| 90998 (CLASSIC CAST PRESS) |

| Value Turret Press (250 RPH) |

| 90932 (4-hole Turret Press with Auto Index) |

| Classic Turret Press (250 RPH) |

| 90304 (Classic Turret Press Kit) 90064 (Classic Turret Press) |

| Ultimate Turret Press (250 RPH) |

| 91910 (5 Station Ultimate Turret Press) 92097 (6 Station Ultimate Turret Press) |

| Pro 1000 Press (500+ RPH) |

| Pro 4000 Press (500+ RPH) |

| 90900 (Pro 4000 Press Only) |

| Six Pack Pro Press (500+ RPH) |

| Shell Plates and Holders |

|---|

| Priming Tool Shell Holder |

| 90213 (#13) |

| Universal Press Shell Holder |

| 90199 (R13) |

| X-Press Shell Holder (APP) |

| 91546 (#13) |

| Pro 1000 Shell Plate |

| Auto Breech | Pro 4000 Shell Plate |

| 90649 (Pro 4000 Shell Plate 13) |

| Six Pack Pro Shell Plate |

| Inline Bullet Feed |

|---|

| Inline Bullet Feed Die |

| 91997 (45CAL) |

| Inline Bullet Feed Kit |

| 92009 (45 CAL) |

| Inline Bullet Feed Magazine |

| 92016 (Large Inline Bullet Magazine) |