You have no items in your shopping cart. close

9MM Luger

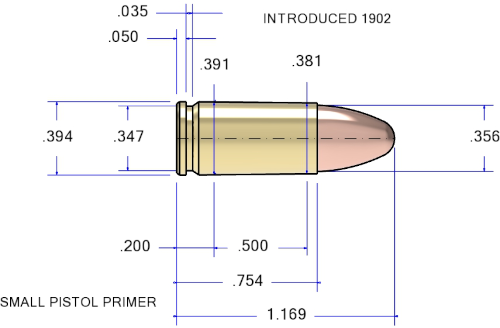

The 9mm Luger, also known as the 9x19mm Parabellum, is one of the most widely used handgun cartridges in the world. Developed by Georg Luger in 1901, it was originally designed for the Luger semi-automatic pistol. The cartridge has a bullet diameter of 9.01 mm (0.355 inches) and a case length of 19.15 mm.

The 9mm Luger is favored for its balanced performance, offering a good combination of manageable recoil, accuracy, and stopping power. It is popular in both civilian and military applications, used extensively in handguns and submachine guns. Common use cases include self-defense, law enforcement, military service, and competitive shooting sports.

The cartridge typically fires a bullet weighing between 115 to 147 grains, with muzzle velocities ranging from 1,100 to 1,300 feet per second, depending on the load. The 9mm Luger is known for its versatility and availability, making it the standard issue for many police agencies and militaries worldwide.

In summary, the 9mm Luger is a highly effective, versatile, and widely-used cartridge suitable for various functions including self-defense, law enforcement, and competitive shooting.

The 9mm Luger is favored for its balanced performance, offering a good combination of manageable recoil, accuracy, and stopping power. It is popular in both civilian and military applications, used extensively in handguns and submachine guns. Common use cases include self-defense, law enforcement, military service, and competitive shooting sports.

The cartridge typically fires a bullet weighing between 115 to 147 grains, with muzzle velocities ranging from 1,100 to 1,300 feet per second, depending on the load. The 9mm Luger is known for its versatility and availability, making it the standard issue for many police agencies and militaries worldwide.

In summary, the 9mm Luger is a highly effective, versatile, and widely-used cartridge suitable for various functions including self-defense, law enforcement, and competitive shooting.

question_answer Join Discussion (1 comment) add remove

Welcome to our cartridge knowledge base, featuring expert insights from M. L. (Mic) McPherson on a wide range of cartridges. Whether you're new or experienced, discover practical tips and share your field experiences to enrich our community. Please no disparaging remarks on other writers and no powder load data. Help shape a valuable resource for all enthusiasts. If you find anything factually incorrect, we want to hear about it! If you have any interesting comments or reloading tricks that you would like to share on this cartridge, share them here!

Please Log in to post a comment.- format_quoteformat_quote

| Die Sets |

|---|

| Lee Full-Length Sizing Die Set |

| 90509 (Carbide 3-Die set) 90963 (Carbide 4-Die set) |

| Lee Breech Lock Die Set |

| 91882 (Carbide 3-Die set) 91934 (Carbide 4-Die set) 92512 (Carbide 4-Die set) |

| Lee Loader |

| 90254 |

| Single Dies |

|---|

| Full-Length Sizing Die |

| Carbide Sizing Die |

| 90548 |

| Powder through Expanding Die |

| 90580 |

| Charging Die |

| Precision Bullet Seating Die |

| 92470 |

| Seating Die |

| 92470 |

| Factory Crimp Die |

| 90860 (Carbide) 92128 (Micrometer Adapter) 92205 (Carbide) |

| Taper Crimp Die |

| 90780 |

| Die Accessories |

|---|

| Micrometer Adjuster |

| 92128 92150 |

| Guided Decapper |

| 91581 |

| Case Conditioning Tools |

|---|

| Case Length Gauge and Shell Holder |

| 90153 |

| Quick Trim Die |

| 90032 |

| Shell Plates and Holders |

|---|

| Priming Tool Shell Holder |

| 90023 (#19) |

| Universal Press Shell Holder |

| 90004 (R19) |

| X-Press Shell Holder (APP) |

| 91552 (#19) |

| Pro 1000 Shell Plate |

| 90669 (Pro 1000 Shell Plate #19) |

| Auto Breech | Pro 4000 Shell Plate |

| 90944 (Pro 4000 Shell Plate 19) |

| Six Pack Pro Shell Plate |

| 91851 (19S) |

| Inline Bullet Feed |

|---|

| Inline Bullet Feed Die |

| 91995 (35CAL) |

| Inline Bullet Feed Kit |

| 92007 (35CAL ) |

| Inline Bullet Feed Magazine |

| 92015 (Medium Inline Bullet Magazine) |