You have no items in your shopping cart. close

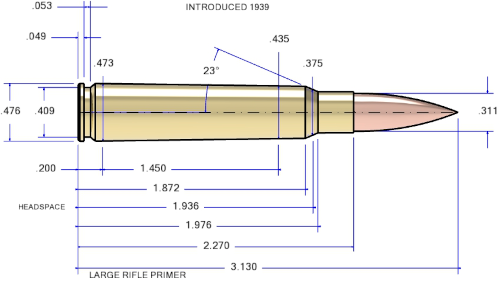

7.7MM Japanese

The 7.7mm Japanese cartridge, also known as the 7.7x58mm Arisaka, was used primarily by the Imperial Japanese Army during World War II. It was developed to replace the 6.5x50mm Arisaka cartridge for greater stopping power and range. The 7.7mm cartridge was used in several Japanese firearms, including the Type 99 rifle and the Type 92 and Type 99 machine guns.

The cartridge has a 7.92mm (.311 inch) diameter bullet and uses a rimless, bottlenecked case design. It is a versatile round compatible with both bolt-action rifles and machine guns, providing a balance between power and control, making it effective for various combat scenarios. The 7.7mm cartridge offers greater ballistic performance compared to its 6.5mm predecessor, useful for engaging targets at longer distances with improved lethality.

Overall, the 7.7mm Japanese cartridge was a significant upgrade in ammunition for Japan during WWII, providing their infantry with improved firepower.

The cartridge has a 7.92mm (.311 inch) diameter bullet and uses a rimless, bottlenecked case design. It is a versatile round compatible with both bolt-action rifles and machine guns, providing a balance between power and control, making it effective for various combat scenarios. The 7.7mm cartridge offers greater ballistic performance compared to its 6.5mm predecessor, useful for engaging targets at longer distances with improved lethality.

Overall, the 7.7mm Japanese cartridge was a significant upgrade in ammunition for Japan during WWII, providing their infantry with improved firepower.

question_answer Join Discussion (1 comment) add remove

Welcome to our cartridge knowledge base, featuring expert insights from M. L. (Mic) McPherson on a wide range of cartridges. Whether you're new or experienced, discover practical tips and share your field experiences to enrich our community. Please no disparaging remarks on other writers and no powder load data. Help shape a valuable resource for all enthusiasts. If you find anything factually incorrect, we want to hear about it! If you have any interesting comments or reloading tricks that you would like to share on this cartridge, share them here!

Please Log in to post a comment.- format_quoteformat_quote

| Die Sets |

|---|

| Lee Full-Length Sizing Die Set |

| 90733 (3-Die set) 92408 |

| Lee Micrometer Neck Sizing Die Set |

| Lee Breech Lock Die Set |

| Lee Ultimate 4-Die Set |

| Lee Loader |

| Single Dies |

|---|

| Full-Length Sizing Die |

| 91085 Ez X Expander: SE2358 |

| Sizing Die |

| Neck Sizing Die |

| Charging Die |

| 90194 (Long Charging Adapter) |

| Precision Bullet Seating Die |

| 92332 |

| Factory Crimp Die |

| 90847 (Collet Style) |

| Die Accessories |

|---|

| Micrometer Adjuster |

| 92215 |

| Case Conditioning Tools |

|---|

| Case Length Gauge and Shell Holder |

| 90115 |

| Quick Trim Die |

| 91368 |

| Presses |

|---|

| Reloader Press (50 RPH) |

| 90045 (Lee Reloader Press) |

| Hand Press (50 RPH) |

| Breech Lock Hand Presses |

| Challenger Press (50 RPH) |

| 90588 (Challenger III) 90050 (50th Anniversary Challenger Kit) 90030 (Challenger Kit) |

| Classic Cast Press (50 RPH) |

| 90998 (CLASSIC CAST PRESS) |

| Value Turret Press (250 RPH) |

| Classic Turret Press (250 RPH) |

| 90304 (Classic Turret Press Kit) 90064 (Classic Turret Press) |

| Ultimate Turret Press (250 RPH) |

| Pro 1000 Press (500+ RPH) |

| Pro 4000 Press (500+ RPH) |

| Six Pack Pro Press (500+ RPH) |

| Shell Plates and Holders |

|---|

| Priming Tool Shell Holder |

| 90202 (#2) |

| Universal Press Shell Holder |

| 90519 (R2) |

| X-Press Shell Holder (APP) |

| 91535 (#2) |

| Pro 1000 Shell Plate |

| Auto Breech | Pro 4000 Shell Plate |

| Six Pack Pro Shell Plate |

| Inline Bullet Feed |

|---|

| Inline Bullet Feed Die |

| 91999 (30CAL) |

| Inline Bullet Feed Kit |

| 92011 (30CAL) |

| Inline Bullet Feed Magazine |

| 92015 (Medium Inline Bullet Magazine) |

| Bullet Casting |

|---|

| Classic Bullet Sizing Kit |

| Breech Lock Bullet Sizer and Punch |

| Bullet Molds |