format_quoteOne of a long list of cartridges improved by Parker Otto (P. O.) Ackley, chiefly through the 1950s, the 257 Ackley Improved comes very, very close to duplicating performance of the 25-06 in a much shorter, more efficient cartridge with a longer neck that will give much longer barrel life. When loaded to the same pressure using the best propellant and the same bullets fired from the same length barrel, the ballistic difference is meaningless.

While the 25-06 has a bit more usable capacity when both are loaded to standard length, the bullet fired from the 257 has half-an-inch more barrel to accelerate through — the result is ballistically a wash. Hard to argue how the 25-06 could in any way be deemed the superior choice.

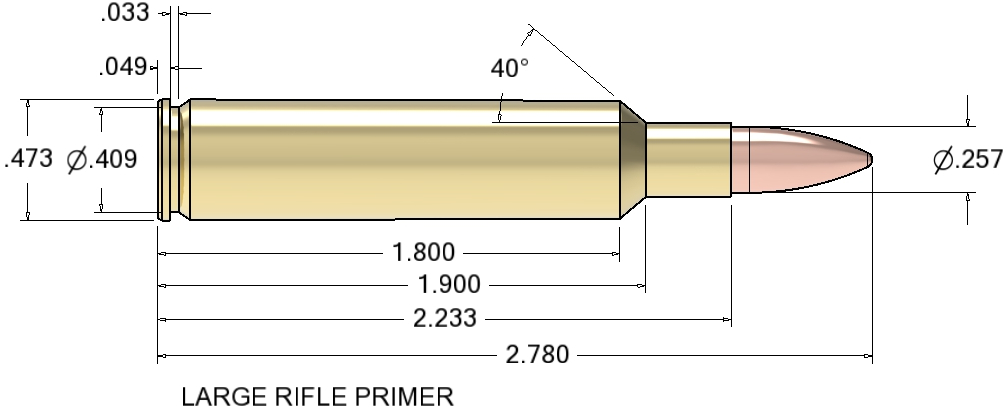

Ackley’s design was genius. He reduced case-body taper to about 0.001-inch per 0.1-inch length, which works perfectly to allow easy extraction, even with loads generating very high pressure. Once the camming action of the bolt has withdrawn the case as far as it will, the case is free of the chamber. Ackley also incorporated a sharper and superior, 40-degree, shoulder.

Factory ammo would chamber in the AI gun with solid headspace control. The case first engages the chamber at the junction of the shoulder and neck. Then the case shoulder and body flex to allow easy and full chambering; on rimless-bottlenecked cases that headspace on the shoulder, this technique prevented case stretching when the round fired.

Ackley often reduced neck length on rimmed cases, when doing so was possible without shortening the neck too much.

The problem was, gunsmiths refused to bother to read and follow the chambering instructions Ackley included with his reamer designs. With bottlenecked rimless designs, to correctly rechamber a barrel from the original chambering to the AI version, it is necessary to remove the barrel from the gun, move the shoulder forward enough to allow the barrel to screw into the action one additional turn and then shorten the barrel shank the same amount.

With rare exception, so-called gunsmiths were wont to do this. They ruined an endless stream of guns by simply running the AI reamer into the unaltered barrel. As such, cases stretched significantly and dies made to correctly size AI cases drove the shoulder back so far case life was extremely limited.

Because of this, the AI concept got a bad and entirely undeserved reputation. The bad reputation belonged to the so-called gunsmiths who had a shingle, a nail, and a Colt 45 Revolver to use as a hammer to drive in the nail so they could hang their shingle.

The AI design is just about perfect and it is a shame it was tarnished by wanna-be backyard hacks.

Generally, AI designs are superior in all ways when chambered correctly. However, I must add one note of caution, Ackley and others of the era were dangerously lax when it came to respecting the value of proof-testing. Many of the recommended loads of that era generated pressure far exceeding Proof-Load Pressure.

Many decades ago, one of the bullet makers was sued when a customer used its data to load for the 257 AI using a propellant that generated phenomenal ballistics. Unfortunately, that listed load also generated pressure exceeding normal proof-loads for the 257 Roberts or any other commercial chambering. This was common practice for the era. Just plain bad luck caught up with that company and the unfortunate shooter.

The gun failed and the shooter was killed. There was no arguing the matter, the published load was patently unsafe because it entirely circumvented any value of proof-testing with normal Industry-Proof-Loads. The result was inevitable. Any one of tens of thousands of handloaders could have been that unlucky guy. Any one of the many Companies publishing such data could have been the unlucky one.

As it was, the company involved was sued for $5,000,000 and ruined. It had to sell out and therefore lost control over a lifetime of investment. It has never entirely recovered.

Refer to the 22-250 discussion for another example of the catastrophic consequences to which the habitual use of loads exceeding the pressure for which a gun has been proof-tested can lead.

Heritage of this case dates to the 1870s with the introduction of the 40-70 Ballard case.

format_quote